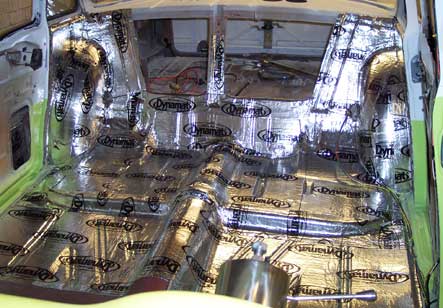

After getting the drivers side windows done last week, I planned to get the passenger ones done and out of the way this weekend. It’s Mothers Day on Sunday, so I only have a few hours to work on the car so I should have been able to get it done easily. I had both windows done and fitted and the channels ready to go in within an hour, so was happy with progress. I couldn’t get the rear door open far enough to fit the channel and it was raining heavily so it will have to wait for another day. With that done I emptied the car out and gave the roof a good clean with panel wipe ready to put the soundproofing on. I had nearly run out of Dynamat, so I bought some cheaper stuff called eDead. It’s much thinner and nowhere near as good it seems from my non scientific testing of tapping the panels and listening for vibration. I doubled up in a strip down the centre which definately improved it, so if I have any Dynanat left afterI do the boot I’ll put some in the centre.

With that done, a quick tidy up and then taped up the last of the wiring in the back of the car now that there are hopefully no more to go in. I decided to pull the tank and see if I could work out why my new sender did not work, and with it dropped on to the floor it seemed to be broken or not connected to earth on the tank. With the sender out, it showed the correct resistance, it just had no metal to metal contact as the crews were O ringed. I pulled one of them off and put it all back together and it worked perfectly. An hour later I managed to finally get the straps back in due to me forgetting to get longer coach bolts and struggling to hold up the tank, pull the strap tight and fit the nut to so little thread. Ah well, done now, will put it on my list.

It needed to tie into a lot of the existing wiring, so it was a pain to cut into it and keep the wiring neat. With it all done, I powered it all up. No flash from the indicators and no LED or siren but the central locking worked from the remote.. After 20 minutes or so of double checking, I realised I had crossed over the battery and ignition live wires. With it swapped over the siren chirped and the led showed status. I unlocked it again and started to tidy up the wiring a bit. The alarm is smart enough to re-lock and re-arm if you haven’t opened one of the doors. Well, it re-armed and while I was thinking about what it might have been I set off the motion detector and the siren which I was right next to went off and scared the living daylights out of me. With that all done, I cleaned up the drivers door inner and vacced it out ready to fit the Dynamat. It makes an audible difference to the doors, they make a nice thud when you shut them instead of sounding hollow and rattly. Just one more door left to do and it’s on to the boot. The engine went out for machining and balancing this week, so I should get that back in a few weeks ready to go straight in. Getting closer all the time.

It needed to tie into a lot of the existing wiring, so it was a pain to cut into it and keep the wiring neat. With it all done, I powered it all up. No flash from the indicators and no LED or siren but the central locking worked from the remote.. After 20 minutes or so of double checking, I realised I had crossed over the battery and ignition live wires. With it swapped over the siren chirped and the led showed status. I unlocked it again and started to tidy up the wiring a bit. The alarm is smart enough to re-lock and re-arm if you haven’t opened one of the doors. Well, it re-armed and while I was thinking about what it might have been I set off the motion detector and the siren which I was right next to went off and scared the living daylights out of me. With that all done, I cleaned up the drivers door inner and vacced it out ready to fit the Dynamat. It makes an audible difference to the doors, they make a nice thud when you shut them instead of sounding hollow and rattly. Just one more door left to do and it’s on to the boot. The engine went out for machining and balancing this week, so I should get that back in a few weeks ready to go straight in. Getting closer all the time.

I used a trestle with a wooden block clamped on to hold my soldering helper up high enough to hold the wiring as I was doing it, and after cutting loads of heatshrink up ready I settled down sat on the crossmember and got on with the job. I’d cut the bundles in slightly different places so that I didn’t end up with a thick part in the loom when the heatshrink was on. A few hours later it was all done and wrapped up with tape and I moved on to the connections to the new wiring for relays and all the other bits. With these done it’s pretty much ready to go now. I pulled the column back out and dynamatted the drivers side and bundled up the wiring loosely until the central locking is in, which should be the last of the wiring. For now at least anyway. Oh, and I turned the brake booster up the right way. Ahem.

I used a trestle with a wooden block clamped on to hold my soldering helper up high enough to hold the wiring as I was doing it, and after cutting loads of heatshrink up ready I settled down sat on the crossmember and got on with the job. I’d cut the bundles in slightly different places so that I didn’t end up with a thick part in the loom when the heatshrink was on. A few hours later it was all done and wrapped up with tape and I moved on to the connections to the new wiring for relays and all the other bits. With these done it’s pretty much ready to go now. I pulled the column back out and dynamatted the drivers side and bundled up the wiring loosely until the central locking is in, which should be the last of the wiring. For now at least anyway. Oh, and I turned the brake booster up the right way. Ahem.

It was then on to some additional wiring. I ran switch wires for the fuel pump and the amplifier power up relays in the boots. The battery is going in the boot so it will be supplied from there too. I fitted a 30A breaker to cover both circuits and left it all loose for now until the battery is in place. Next was a relay to do the neutral start switch and supply a signal to the PCM to indicate if the car is in gear or not and control the idle. It also has a two way brake switch that supplies power to the torque converter clutch which I fitted. With all that done, I sat back and realised I’d done all of the wiring I needed for now and could move on to the PCM loom. I planned to use the hole from the wipers to feed the wiring through, which I’d checked was wide enough for the wiring. It wasn’t big enough to get any of the plugs through, so it was either make a bigger hole or cut all those wires. I grouped the wires by colour so that I could solder them back together easily and cut it all. Gulp. Plenty of soldering for me to do over the next few weeks!

It was then on to some additional wiring. I ran switch wires for the fuel pump and the amplifier power up relays in the boots. The battery is going in the boot so it will be supplied from there too. I fitted a 30A breaker to cover both circuits and left it all loose for now until the battery is in place. Next was a relay to do the neutral start switch and supply a signal to the PCM to indicate if the car is in gear or not and control the idle. It also has a two way brake switch that supplies power to the torque converter clutch which I fitted. With all that done, I sat back and realised I’d done all of the wiring I needed for now and could move on to the PCM loom. I planned to use the hole from the wipers to feed the wiring through, which I’d checked was wide enough for the wiring. It wasn’t big enough to get any of the plugs through, so it was either make a bigger hole or cut all those wires. I grouped the wires by colour so that I could solder them back together easily and cut it all. Gulp. Plenty of soldering for me to do over the next few weeks!