I only had a few hours on Saturday, so the plan was to drill the holes for the power steering reservoir and test it with the engine running, then hopefully get some more time a bit later in the night to do some more. With the reservoir mounted, I filled it right to the brim ready to fill the empty pipes, then got the engine ready to fire again as I have now fitted the new street and performance headers. I’d welded, painted and fitted the steering linkage one night in the week, so it was all going in hopefully to stay. I pulled all the plugs and re-gapped them for the blower and the MSD, and tightened up the headers and moved a few cables that were now in the way with the new run. A quick double check, then check again, and it was ready to fire. It started easily as it always does, and sounded superb. Power steering works as expected, and no leaks that I can see which is good. A quick top up of the fluid and thats another one off the list.

The next thing I wanted to do was the horn button. Easy eh?. I put the assembly back together and tested it, and there was no way to get the signal from the Flaming River rack to the button. I left it and went and had my tea, then went back out to have another quick look at it. I ended up drilling two small holes and soldering a wire between the two so that the button on the wheel would work. A quick test fit, and it didnt work, which I convinced myself was a bad earth, so tightened the centre bolt. It was then I realised I’d put the spring on the wrong side of the contact plate and it was pushing it away from the contact. The wheel was on solid, and I had no puller. I yanked it, tapped it gently, and tried to use the screw holes in the wheel to get it off with no luck for 4 hours. I was desperately trying not to chip the paint, but it wasnt budging. After bending 3 or 4 bolts trying to shift it, I cut down a bracket by hand and filed it to make a puller and off it popped. I re-made the wire just in case I’d broken it, and fitted it this time making sure it worked properly before tightening it down. It was now 2am and I was knackered. Sunday I wired up the horns themselves, which sound great and had a massive tidy up before working on the F100 which is off to be blasted tomorrow. Funny how the easy jobs can take so much time!

Next was making the cooler lines for the transmission. I’d also forgotten to put the fittings on the box, but got the old ones out and the new ones in without too much hassle. I made one of the lines, then spent the next hour trying to get the angle right to connect the fitting on the box. When I finally got it right, I made the other line to match, and spent another hour trying to get that one right as well. Doesn’t seem to be much done, but it took a lot of time. Oh and the new headers are here, so the car’s ready to go to Zane’s for the exhaust.

Next was making the cooler lines for the transmission. I’d also forgotten to put the fittings on the box, but got the old ones out and the new ones in without too much hassle. I made one of the lines, then spent the next hour trying to get the angle right to connect the fitting on the box. When I finally got it right, I made the other line to match, and spent another hour trying to get that one right as well. Doesn’t seem to be much done, but it took a lot of time. Oh and the new headers are here, so the car’s ready to go to Zane’s for the exhaust.

Happy that it hadn’t exploded, I carried on and connected the inlet side. I also connected the blow off valve vacuum so it was ready to go. I’d run out of time, so gave it a real quick test fire. It fired straight up, and idled nicely. The fuel pressure rose as I pulled the throttle, and the blow off valve moved as it came off boost, so its spot on. There was a classic car show just down the road from me on Sunday, so I went down to meet my mate down there and had a wander round the tool stalls. I managed to find some carbide burrs, so when I got back home I pulled all the tubing off again and smoothed it all out with the die grinder. I cut some U channel to cover the edge, and clamped it all back together hopefully for good. While I had the car up in the air I relocated the MSD box to between the inner wing and the firewall, and mounted the fan and headlight fuse box. A quick test fire again to show it off and it sounded great. I need to put all the wiring back again and then the radiator can go back in. Just want to go and rev it up!

Happy that it hadn’t exploded, I carried on and connected the inlet side. I also connected the blow off valve vacuum so it was ready to go. I’d run out of time, so gave it a real quick test fire. It fired straight up, and idled nicely. The fuel pressure rose as I pulled the throttle, and the blow off valve moved as it came off boost, so its spot on. There was a classic car show just down the road from me on Sunday, so I went down to meet my mate down there and had a wander round the tool stalls. I managed to find some carbide burrs, so when I got back home I pulled all the tubing off again and smoothed it all out with the die grinder. I cut some U channel to cover the edge, and clamped it all back together hopefully for good. While I had the car up in the air I relocated the MSD box to between the inner wing and the firewall, and mounted the fan and headlight fuse box. A quick test fire again to show it off and it sounded great. I need to put all the wiring back again and then the radiator can go back in. Just want to go and rev it up!

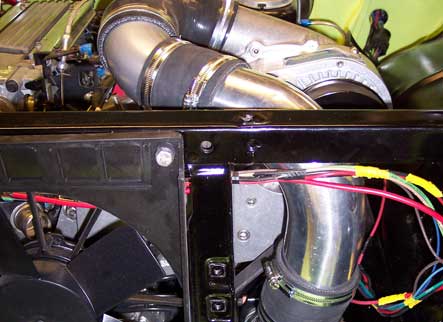

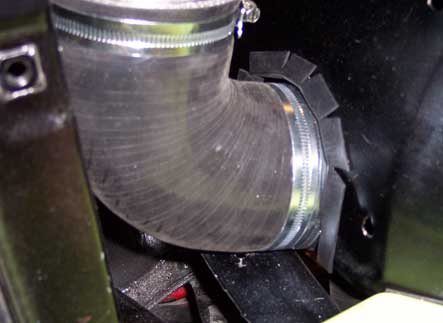

The plan for the intercooler was to go through 180 degrees and then 90 degrees straight up through the frame horns, or just behind them. Unfortunately it ended up too close to the A arms, so that idea was out. The only other option was to come through the bottom edge of the inner wing, so that was what I decided to do once I worked out where the pipes would sit. The outlet from the procharger either had to go across the engine, or go through 180 degrees then down. Also I couldnt get the engine inlet elbow to clear the procharger if it faced towards it so it had to be 180. After much testing and re-positioning I worked out it could either go in front of the radiator, which blocked the radiator hose, or in front of the core support filler panel where the MSD box was. There wasn’t enough room to fit the hose between the MSD and the procharger, so that had to come out. I was more concerned about having the MSD hidden than anything else for some reason. Don’t ask me why, it just does!. I’m still half tempted to run without the intercooler, but where’s the fun in that?

The plan for the intercooler was to go through 180 degrees and then 90 degrees straight up through the frame horns, or just behind them. Unfortunately it ended up too close to the A arms, so that idea was out. The only other option was to come through the bottom edge of the inner wing, so that was what I decided to do once I worked out where the pipes would sit. The outlet from the procharger either had to go across the engine, or go through 180 degrees then down. Also I couldnt get the engine inlet elbow to clear the procharger if it faced towards it so it had to be 180. After much testing and re-positioning I worked out it could either go in front of the radiator, which blocked the radiator hose, or in front of the core support filler panel where the MSD box was. There wasn’t enough room to fit the hose between the MSD and the procharger, so that had to come out. I was more concerned about having the MSD hidden than anything else for some reason. Don’t ask me why, it just does!. I’m still half tempted to run without the intercooler, but where’s the fun in that?