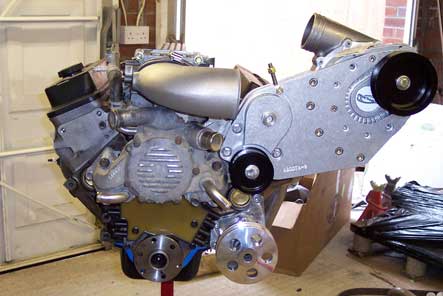

The guy came back and re-fitted the rear screen for me in the week, and then I realised how badly my chrome fitted. It took hours of bending, fitting adn removing to get it OK. I left the front for the weekend and went and had a beer. The LT1 engine has EGR (Exhaust Gas Recirculation) inlets on the back of the manifold that need blanking off, so I set about making some on Saturday. John had given me some flat aluminium bar so I traced out the shapes I wanted and cut it out with the jigsaw before trimming it with the bench grinder. I sanded them both smooth and buffed them too. not that anyone can see them, but I know they are shiney anyway.

While I had the jigsaw out I cut the winged supports from inside the rocker covers without scratching them luckily. I fitted the gaskets and popped them on loosely for now just to keep the dust out. I had the front screen chrome left to do, which was in a sorry state, so I gave it a good clean and polish and tried to get the worst of the dents out before it went on. After a lot of bending and re-fitting I got that to look OK as well, so fitted the wiper escutcheons too. A quick clean of all the glass and I stood back to look at it and was chuffed with how good it looks. It’s easy to be critical of all the little bits and bobs that need doing, but the overall look of the car is great. Next is to work out what fittings I need for the engine and box plumbing and order that up this week ready to hopefully fit them next weekend. All things being equal the motor will stay in then. Can’t wait to see it in place and get on with wiring and plumbing it.